I. Product structure and principle

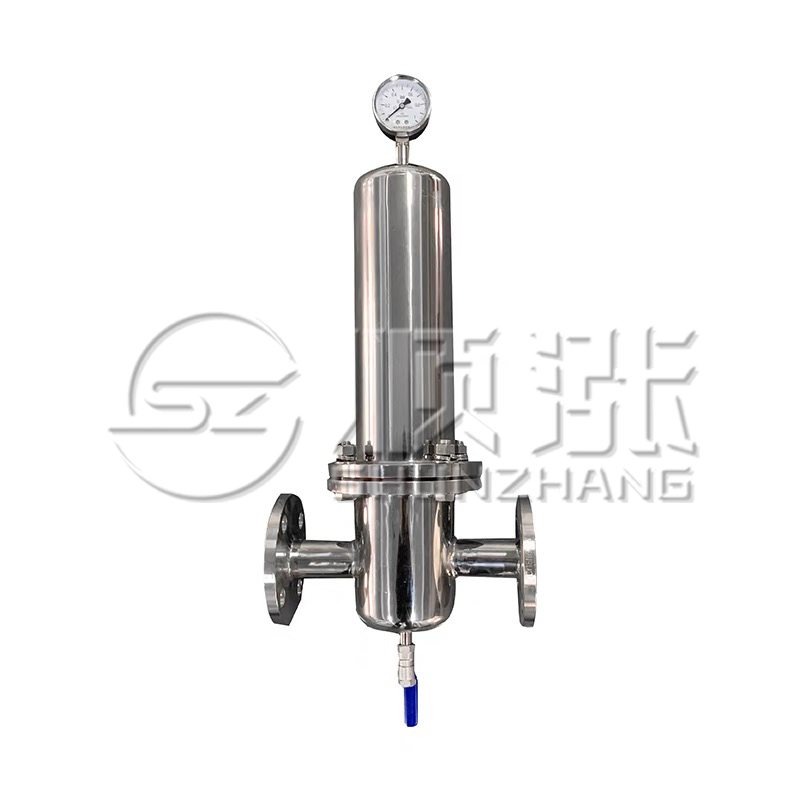

The main body of the steam filter is meticulously made of high-quality stainless steel (304/316L), equipped with a high-precision pressure gauge for real-time monitoring of internal pressure changes, and flange interfaces on both sides to ensure a solid connection with the pipeline. The internal filter element is made by special technology and has high efficiency filtration performance. Its working principle is: steam containing impurities from the inlet into the filter, under pressure, the steam through the filter element, while rust, welding slag, particles and other impurities are intercepted on the surface of the filter element, clean steam from the outlet outflow, to protect the back-end equipment from impurities damage, to ensure stable operation of the steam system.

II. Performance Advantages

- Excellent material and durabilityThe corrosion-resistant 304 or 316L stainless steel is selected to withstand high-temperature and high-pressure steam environments for long service life.

- Pressure monitoring for safety and reliability: The top pressure gauge displays the internal pressure in real time, making it easy to detect blockage or abnormality in time and guaranteeing the safety of the system.

- Highly efficient filtration with selectable precisionThe filter cartridges are available in a wide range of filtration accuracies (e.g., 5 μm - 100 μm), which can be selected according to the needs, and effectively intercept various impurities.

- Easy to install and easy to maintain: Flange interface design, easy to install; regularly open the device, replace or clean the cartridge can be, easy to operate.

III. Application scenarios

- Chemical industry: Filtering impurities in steam, protecting equipment such as reactors and heat exchangers, and ensuring smooth chemical production.

- Food & Beverage Industry: Used in steam heating systems to ensure pure steam, avoid contamination of food and beverages, and comply with hygiene standards.

- Pharmaceutical industry: Filtering steam impurities during the pharmaceutical production process to meet the strict requirements for steam quality in pharmaceutical facilities.

- Power industry: Protects equipment such as turbines from wear and tear caused by solid particles in the steam and improves power generation efficiency.

- printing and dyeing industry: Ensure steam purity, avoid impurities affecting printing and dyeing quality, and improve product qualification rate.

IV. Operation and maintenance

- easy operation: Once the equipment is properly connected to the piping, it can be put into operation, and the steam passes through normally in the direction of flow to achieve filtration.

- Easy maintenance: Observe the pressure gauge regularly, if the pressure rises abnormally, close the inlet and outlet valves, open the filter, take out the cartridge for cleaning (available compressed air blowing) or replacement, and at the same time, check the status of the seals to ensure that the seal is good.

V. Technical parameters

| Main material | 304 stainless steel / 316L stainless steel |

| Filtration accuracy | 5μm, 10μm, 20μm...100μm |

| work pressure | Conventional 0.6MPa - 1.6MPa (higher pressure can be customized, material thickness and structure design need to be confirmed) |

| operating temperature | Maximum withstand 250 ℃ (304 stainless steel conventional range, special working conditions can be selected to enhance the high temperature resistant materials) |

| interface method | Flange connections (e.g. DN25 - DN200 etc.) |

| Filter material | Titanium rods, PTFE, etc. |