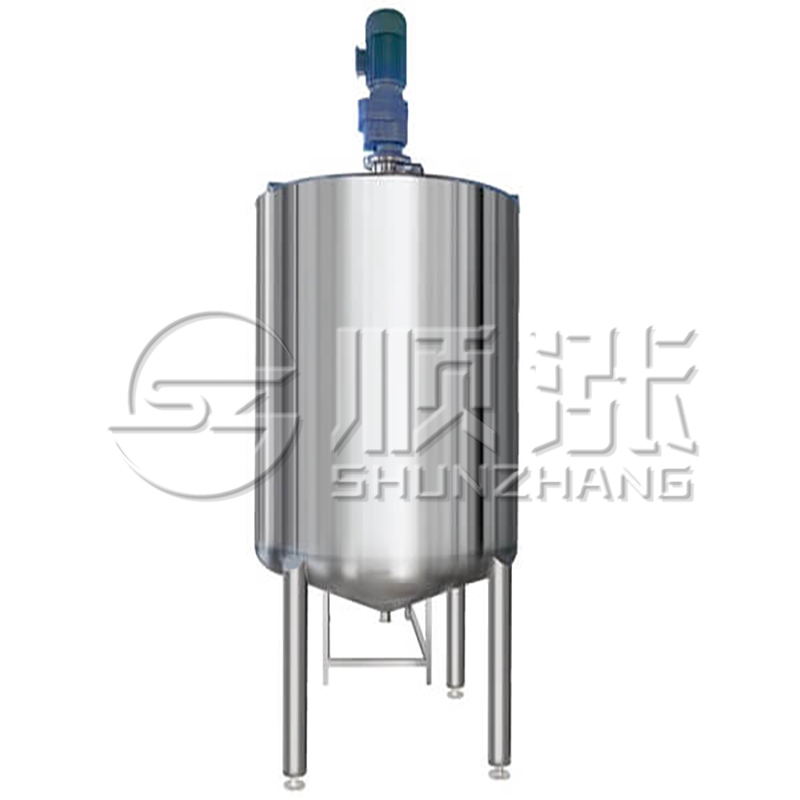

The main body of this single-deck mixing tank is made of high-quality 304 or 316L stainless steel with excellent corrosion resistance, which can effectively resist the erosion of various chemicals and ensure long-term stable operation, and at the same time, it meets the standards of the food, pharmaceutical and other industries with very high hygiene requirements. The top of the tank adopts open lid design, which makes it convenient to add materials, take samples and clean and maintain the inside of the equipment. Equipped with high-efficiency stirring device, driven by a powerful motor, through the stirring shaft to drive the rotation of a specific shape of the stirring paddle, according to the characteristics of the material and process requirements, to achieve uniform mixing of materials, dispersion, dissolution and other operations. Widely used in chemical raw material mixing, food ingredient mixing, pharmaceutical preparation blending and other scenarios, its simple and practical design for all kinds of industrial production and laboratory research provides a reliable material handling solutions, is to improve production efficiency and product quality of the powerful equipment.

I. Product structure and principle

- Product Mix:The main body of the single layer mixing tank is made of high quality 304 or 316L stainless steel with good corrosion resistance and strength. The tank is cylindrical in shape, and the bottom can be designed as conical or flat bottom according to requirements. The top of the tank adopts open lid structure, which is convenient for putting in and taking out materials as well as cleaning and checking inside the equipment. The mixing device is installed on the top of the tank, which is mainly composed of motor, reducer, mixing shaft and mixing paddle. The motor transmits the power to the mixing shaft through the reducer and drives the mixing paddle to rotate in the tank.

- How it works:Through the rotation of stirring paddles, liquid flow of different directions and intensities is generated, so that the materials in the tank are subjected to shearing, extrusion, diffusion and other effects, thus realizing the mixing, dispersing, dissolving and other operations of the materials. Different shapes and angles of the paddle can produce different flow fields to adapt to different material characteristics and process requirements. For example, the propeller paddle can produce axial flow, suitable for the need for rapid mixing of low-viscosity materials; turbine-type paddle to produce radial flow, the mixing and dispersion of high-viscosity materials with better results.

II. Performance Advantages

- Excellent materialThe choice of 304 or 316L stainless steel, corrosion resistance, can avoid material contamination, in line with the hygiene standards of food, pharmaceutical and other industries, and long service life.

- Easy to openTop-opening lid design, easy for operators to quickly add materials, sampling and testing, as well as deep cleaning and maintenance of the interior of the tank, to improve work efficiency.

- Highly efficient mixingPowerful mixing device, the rotation speed can be adjusted according to the actual demand, with different types of mixing paddles, can meet the requirements of a variety of materials mixing process, to ensure high uniformity of mixing.

- Structurally soundThe tank adopts reasonable structural design and support method, the legs are solid and can withstand the vibration and external force during the mixing process, which ensures the stable operation of the equipment.

III. Application scenarios

- Chemical industry: Used for mixing, dissolving, dispersing and other operations of chemical raw materials, such as the production process of coatings, inks, adhesives and other products.

- Food industryIt is suitable for mixing and blending of food ingredients, such as jams, condiments, dairy products, etc., to ensure the consistency of food quality and taste.

- Pharmaceutical industry: It can be used for the preparation and mixing of pharmaceutical preparations to meet the strict requirements of pharmaceutical production on hygiene and mixing uniformity.

- labs: In scientific research experiments, it is used for mixing test of small batch materials, providing data reference and process verification for industrial production.

IV. Operation and maintenance

- Easy to operate:Before starting the equipment, make sure that there is no foreign matter in the tank, check whether the mixing device and the parts are firmly connected. During the running process, the speed can be adjusted in real time according to the material mixing situation.

- Maintenance is easy:Clean the inside of the tank regularly, you can use neutral cleaner with a soft cloth to wipe it, avoid scratching the stainless steel surface. Check the wear and tear of the mixing shaft and paddle, and replace the worn parts in time. Regularly lubricate and maintain the motor and reducer according to the instruction manual to ensure smooth operation of the equipment.

V. Technical parameters

| capacity | 100L - 5000L (customizable) |

| material (that sth is made of) | 304 stainless steel / 316L stainless steel |

| Design Pressure | atmospheric |

| Design temperature | Determined according to material characteristics and process requirements |

| stirring speed | 0 - 1000rpm (adjustable) |

| Motor power | 0.55kw - 15kw (depending on volume and mixing requirements) |

| Interface Specifications | Customized according to actual needs |

| Stirring paddle form | Propulsion, turbine, paddle, etc. (on request) |

With scientific structural design and excellent performance, the Single Deck Mixing Tank provides reliable support for multiple industries. As a source manufacturer, we provide direct supply service and support personalized customization. No matter what you need in terms of volume, material, configuration, etc., we can customize according to your needs. For more product information, exclusive quotes, or professional solutions, please feel free to contact us, and we will be happy to help you improve production efficiency and product quality!