This microbial fermenter is made of high quality stainless steel with excellent corrosion resistance, ensuring long-term stable operation and not easy to contaminate the material. The scientific and rational design of the tank is equipped with a number of standard ports, which is convenient for inoculation, sampling, aeration and addition of culture medium to meet the diversified needs of microbial cultivation process. The internal precision mixing system can evenly mix the material and promote the microorganisms and nutrients to fully contact, and at the same time, with the efficient temperature control device, it can accurately maintain the temperature required for fermentation, creating an ideal environment for microbial growth. Widely used in biopharmaceutical, food fermentation, scientific research institutes and other fields, suitable for bacteria, yeast, fungi and other microorganisms culture and fermentation, is to improve the efficiency of microbial fermentation and the quality of the product is the key equipment.

I. Product structure and principle

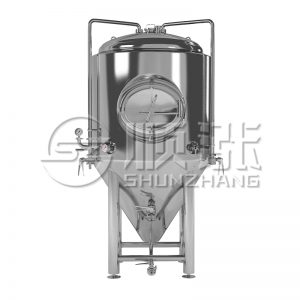

- product mixThe tank is made of high quality stainless steel (e.g. 304 or 316L), equipped with high efficiency mixing device (blue drive system on top), multiple interfaces (aeration, inoculation, sampling, discharging, etc.), temperature-controlled jacket and liquid level observation device.

- Working PrincipleThe microorganisms are provided with a suitable growth environment by precisely regulating parameters such as temperature, pH, dissolved oxygen and stirring speed. The mixing device ensures uniform mixing of materials, the aeration system supplies oxygen, and the temperature control system maintains a constant temperature to promote efficient metabolism of microorganisms and realize the large-scale production of target products (e.g., enzymes, antibiotics, biofuels, etc.).

II. Performance Advantages

- Excellent materialHigh-quality stainless steel is used, which has strong corrosion resistance, avoids material contamination and prolongs the service life of the equipment.

- Precise temperature control: Intelligent temperature control system with sensitive response and high precision of temperature control ensures microorganisms grow and multiply under suitable temperature.

- Highly efficient mixing: Adjustable stirring speed with scientifically designed stirring paddles to realize full mixing of materials, enhance oxygen transfer efficiency and promote fermentation reaction.

- High degree of automationThe system monitors pH, dissolved oxygen, temperature and other key parameters in real time, automatically regulates stirring, aeration, temperature control and other devices, reduces manual intervention, and ensures a stable and controllable fermentation process.

- Easy to clean and maintainSmooth inside of the tank, no dead corners, easy to clean and disinfect, in line with GMP and other hygiene standards, reducing the risk of contamination.

III. Application scenarios

- biopharmaceutical: Used in the production of antibiotics, vaccines, biological drugs, etc., to ensure the quality and yield of drugs.

- food fermentation: Suitable for brewing condiments (e.g. soy sauce, vinegar), fermented dairy products, wines, etc., to enhance the flavor and quality of food.

- scientific research and education: Ideal fermentation laboratory equipment for research institutes and university laboratories to support research and teaching in the fields of microbiology and bioengineering.

- chemical production: Used in the production of amino acids, enzymes, organic acids and other chemical products to meet the needs of industrial production.

IV. Operation and maintenance

- easy operation: Equipped with humanized operation interface, one-key start operation, intuitive and easy-to-understand parameter settings, reducing the threshold of operation.

- Easy maintenance: Regularly clean the internal and external pipes of the tank, check the operating conditions of the mixing motor, seals, sensors and other components, and replace the wearing parts in time to ensure the normal operation of the equipment.

V. Technical parameters

| General design parameters | Design Pressure | Fermenter: according to customer requirements (ATM ~ 1.0MPa) Jacket: according to customer requirements (ATM ~ 0.5MPa) |

| Design temperature | Tank, jacket according to customer requirements (0 ℃ ~ 160 ℃) | |

| makings | liner | 304, 316L |

| jacket | 304 | |

| Legs, etc. | 304 | |

| grout | import and export | Quick Release Clips, Flanges |

| Tank Interface | PH, DO, temperature, inoculation, defoaming, acid replenishment, alkali replenishment, material replenishment, pressure, etc. | |

| surface treatment | Type of treatment | Mechanical polishing, electrolytic polishing, sand blasting, acid washing |

| Polishing precision | Inner wall 0.4μm, outer wall 0.6μm | |

| Stirring paddle form | Paddle form | Disc turbine mixing paddles, defoaming paddles, flat blade paddles, inclined blade paddles, curved blade paddles, etc. |

With its scientific structural design, excellent performance and intelligent control, Microbial Fermenter provides strong support for microbial fermentation process in various industries. Source manufacturers direct supply, support personalized customization, for more product information or to get exclusive offer, please feel free to contact us, we will provide you with professional and efficient microbial fermentation solutions, help improve production efficiency and product quality!

Sixth, the product real photo