I. Product structure and principle

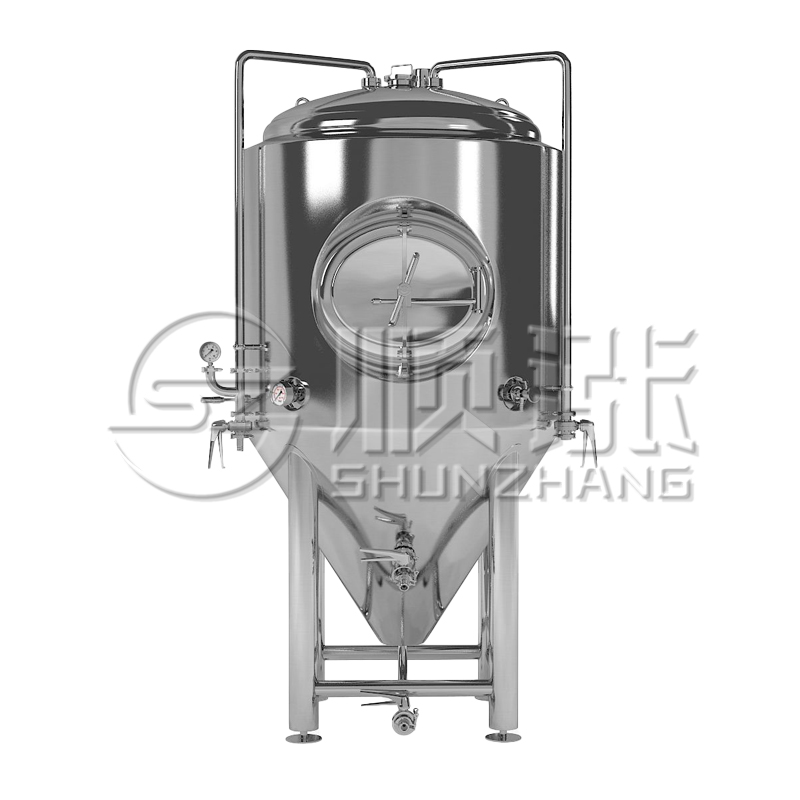

- Product Mix:The main body of the beer fermenter is made of high quality 304/316L stainless steel with excellent corrosion resistance, ensuring a pure environment for beer fermentation. The tank is designed in cylindrical shape with conical bottom, which is convenient for yeast sedimentation and discharge. The exterior of the tank is covered with a highly efficient insulation layer to minimize heat loss, and a precision temperature control device to monitor and accurately regulate the temperature inside the tank in real time. The sealing system and pressure control system work together to isolate external contamination and maintain stable pressure inside the tank.

- How it works:By precisely controlling the temperature, pressure and sealing conditions, an ideal environment is created for the yeast fermentation, which promotes a smooth fermentation process and enhances the flavor and quality of the beer.

II. Performance Advantages

- Excellent materialThe choice of 304/316L stainless steel is corrosion-resistant, avoiding metal contamination of the beer and guaranteeing the purity of the body.

- Precise temperature control: Highly efficient insulation layer combined with precision temperature control device, temperature control range 0℃ - 30℃, accuracy of ±0.5℃, to ensure that the fermentation is carried out at the optimal temperature.

- Excellent sealingStrict sealing design prevents the intrusion of stray bacteria, and the pressure control system stabilizes the pressure inside the tank (0 - 0.3MPa) to promote uniform fermentation and enhance the quality of beer.

- well-designedThe conical bottom is convenient for yeast management, and the manhole and sight glass are convenient for daily observation and cleaning maintenance to ensure equipment hygiene and smooth operation.

III. Application scenarios

Widely used in large-scale beer brewing enterprises, craft beer workshops, scientific research institutions and so on. Whether for large-scale industrial production or small batch craft brewing experiments, it can meet the needs of the main fermentation, post-fermentation and other process requirements, and help brew a unique flavor and stable quality of beer.

IV. Operation and maintenance

Temperature and pressure parameters can be easily set through the control panel during operation, and the fermentation process can be monitored in real time. Regularly clean the inside of the tank, check the seals for deterioration, and maintain the temperature control device and pressure system to ensure the long-term stable operation of the equipment. The easy-to-understand operation interface and convenient maintenance process reduces the threshold of use and improves production efficiency.

V. Technical parameters

| Design Pressure | 0.15 MPa (tank) / 0.09 MPa (jacket) |

| Design temperature | 100°C (tank) / 65°C (jacket) |

| Type of treatment | Mechanical polishing, sandblasting |

| Polishing precision | Inner wall 0.4μm, outer wall 0.6μm |

| Material of the liner | 304, 316L |

| Jacket material | 304 |

| insulation layer | organosilicon |

| Mode of import and export | Quick Release Clips, Flanges |

With its scientific structural design, excellent performance and stable performance, beer fermenter has become a key equipment in the beer brewing process. Source manufacturers direct supply, support personalized customization, for more product information or to get an exclusive quote, please feel free to contact us, we will provide you with professional and efficient beer fermentation solutions to help brew amazing quality beer!