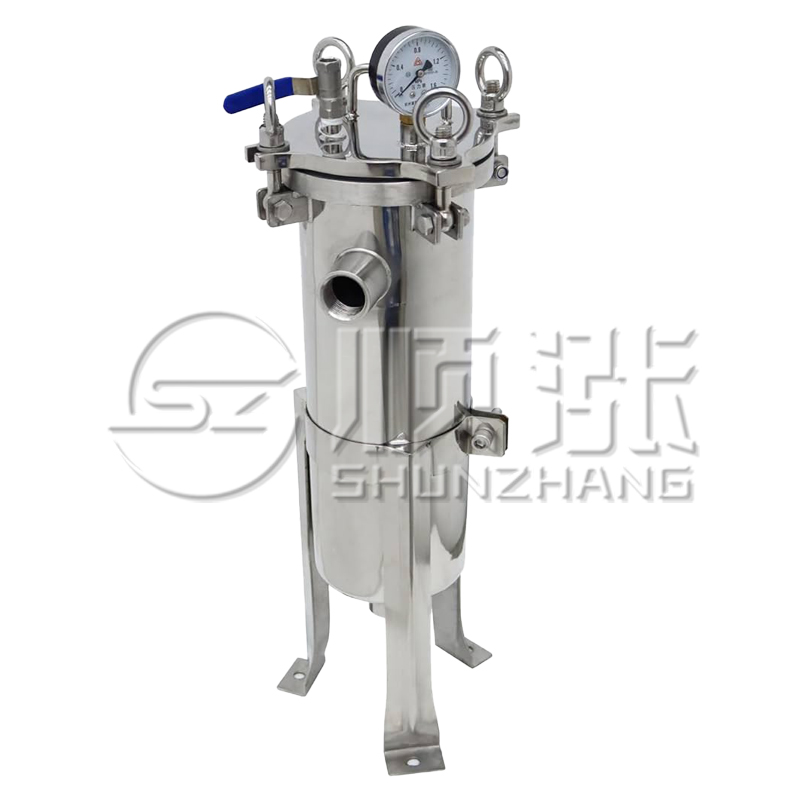

Single bag filter is one of the filtration equipments of Wenzhou Shunhao Machinery Technology Co., Ltd. It is made of high quality stainless steel with excellent corrosion resistance and stability, and is suitable for a variety of complex working conditions. Its single-bag structure design facilitates the rapid replacement and maintenance of the filter element, effectively enhancing the convenience of use. The top pressure gauge can monitor the filtration pressure in real time, assisting the user to control the filtration status accurately; the supporting valve realizes the flexible control of fluid on and off, and the operation is convenient and efficient. Through the precision filtration mechanism, the filter can efficiently intercept impurities and particles in the liquid and ensure the purity of the filtered fluid, which is widely used in chemical, food and beverage, pharmaceutical, water treatment and other industries, providing reliable solutions for various fluid filtration needs.

I. Product structure and principle

- core structureSingle bag filter tank is mostly made of stainless steel 304, 316L with good corrosion resistance, or carbon steel to take into account the strength and cost. The filter bag is made of PP, PE, nylon and other materials according to different usage scenarios, with a filtration precision of 1 - 1000 microns, precisely intercepting impurities. The sealing parts are made of silicone rubber and EPDM rubber seals to prevent leakage. The inlet and outlet ports provide a variety of connection methods such as flanges and quick-fit clamps, which are suitable for all kinds of piping systems.

- Working PrincipleThe medium to be filtered enters from the inlet, passes through the filter bag uniformly under pressure, the impurities are intercepted, and the clean medium flows out from the outlet, realizing solid-liquid or solid-gas separation, with a single filtration efficiency of over 99%.

II. Performance Advantages

- high efficiency filtrationSingle bag design with unique fluid distribution structure can quickly intercept large particles and fine suspended matter, whether it is industrial wastewater or high-purity pharmaceutical filtration, can be a stable output of clean media.

- Pressure stabilization: The internal flow path is optimized for minimal pressure drop during operation and negligible pressure fluctuations over long periods of continuous operation, effectively reducing energy consumption.

- Good durabilityStainless steel is resistant to acid and alkali, oxidation, and carbon steel is treated with special anticorrosive treatment, combined with high strength tank structure, the life span can be up to 8 - 10 years under normal use.

III. Application scenarios

- metallurgyIt is used for filtration of chemical raw materials, solvents, paints and lacquers, etc. It can remove particles and insoluble matter to ensure product quality.

- petrochemical: Filter lubricating oil, fuel, etc., to reduce the wear and tear of impurities on equipment parts and extend equipment life.

- food and drink: Processes fruit juices, wines and dairy products to remove residues and sediments and improve product quality.

- pharmaceutic: Filtration of pharmaceutical solutions, purified water, interception of bacteria, etc., to meet the high purity requirements of pharmaceuticals.

- sewage treatment: Filters sediment and rust from domestic water, removes suspended solids and algae from pool water.

IV. Operation and maintenance

- Easy InstallationSimple structure: Connect the inlet and outlet pipes and tighten the sealing parts according to the instruction manual, and the installation can be completed within 30 minutes.

- Quick ChangeSingle-bag design allows for easy bag changes, with the top cover open for bag changes in less than 10 minutes, minimizing downtime.

- Low maintenance costsNo complex internal structure, only need to check the seal and connection, clean the surface dust, maintenance workload is greatly reduced.

V. Technical parameters

| Filtration accuracy | 1 - 1000μm |

| throughput | 0.5 - 50m³/h |

| work pressure | 0.1 - 1.6MPa |

| operating temperature | -10°C - 120°C |

| Tank material | Stainless Steel 304, Stainless Steel 316L, Carbon Steel |

| Filter bag material | PP (Polypropylene), PE (Polyethylene), Nylon |

| Interface Specifications | DN25 - DN200 (flange connection), φ19 - φ108 (quick release clamp connection) |

| Equipment Diameter | 300 - 1000mm |

| Equipment height | 500 - 2000mm |

| capacity | 5 - 300L |

| pressure drop | ≤0.05MPa (initial) |

Sixth, the product real photo